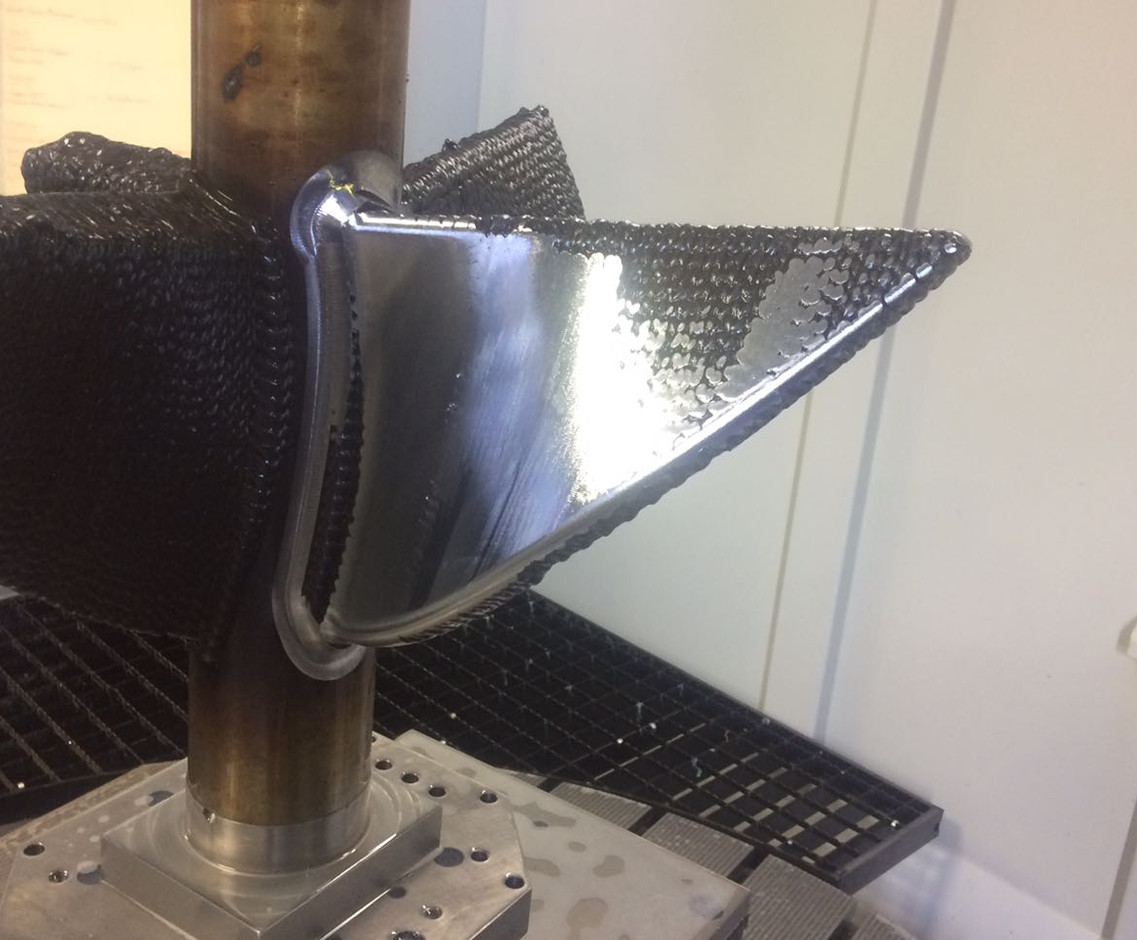

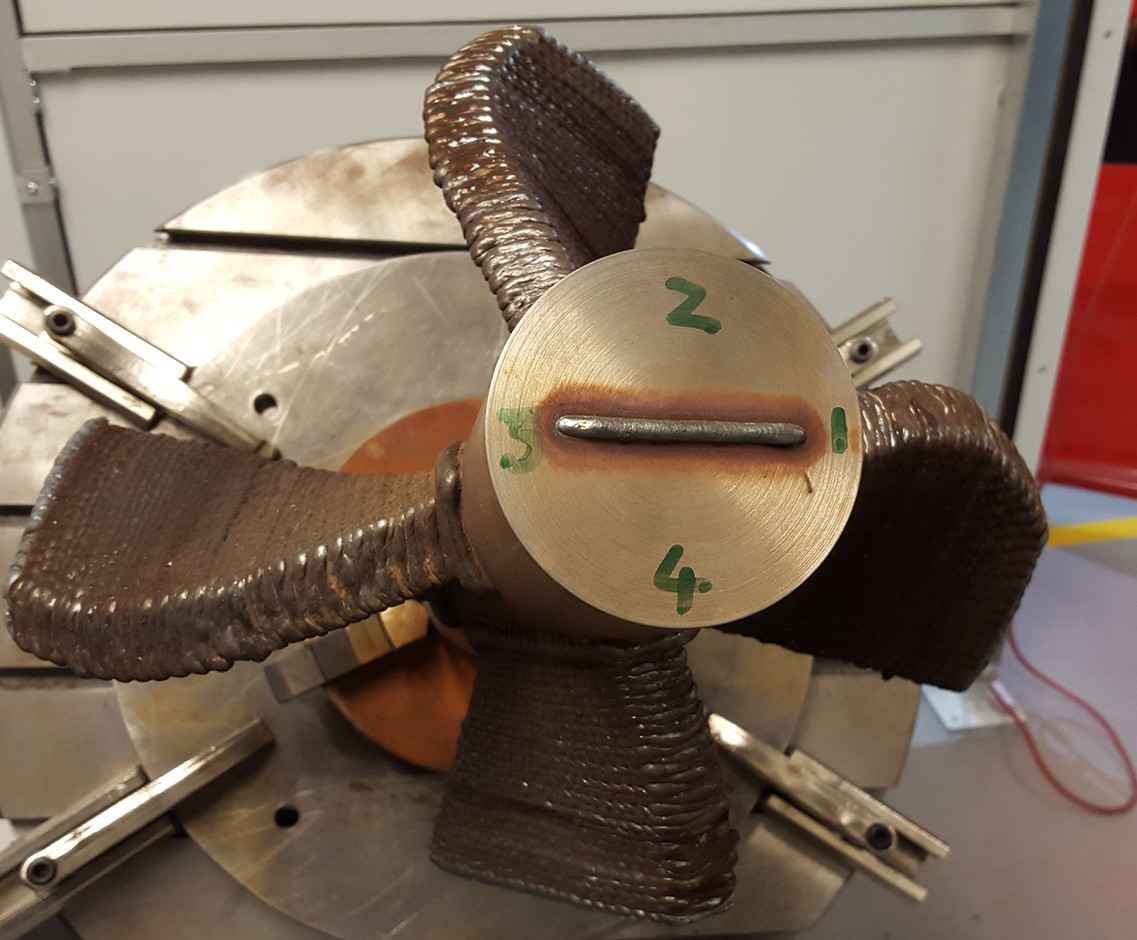

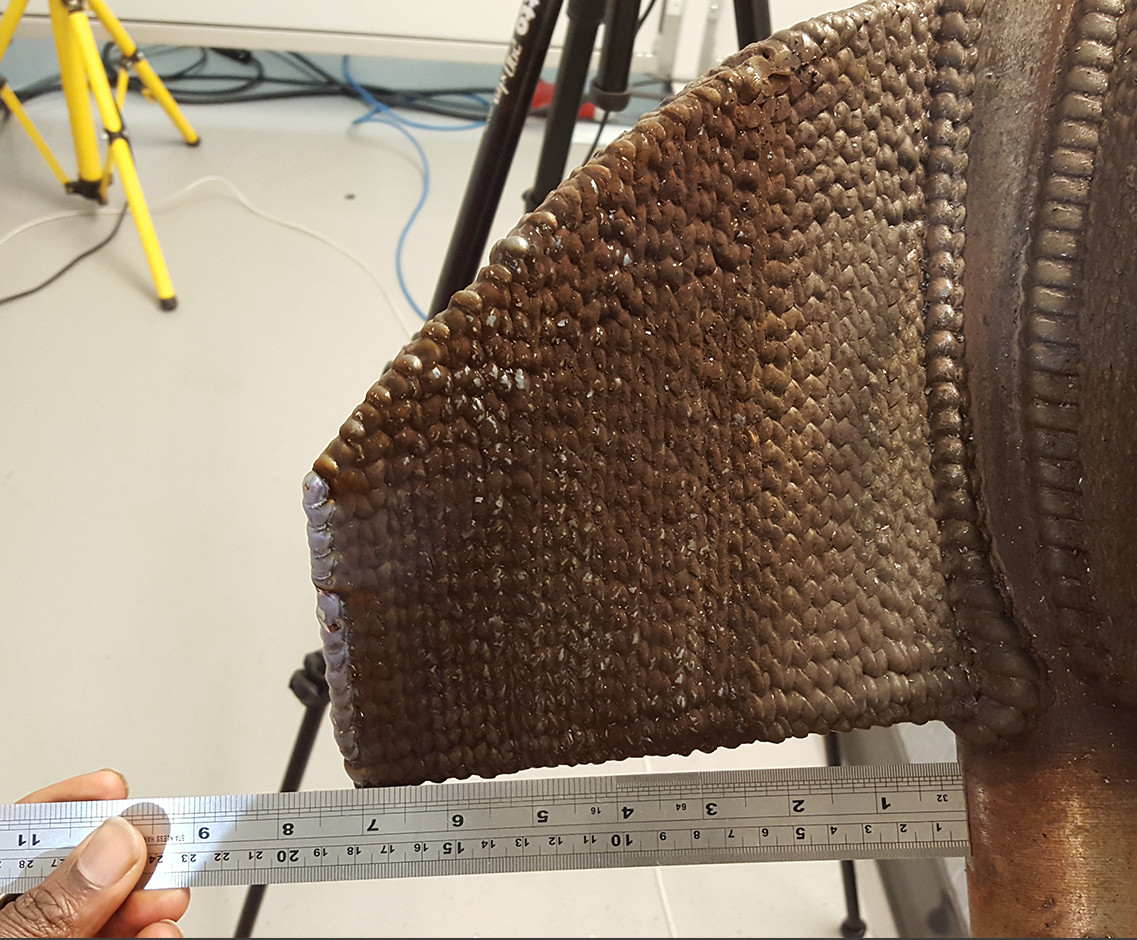

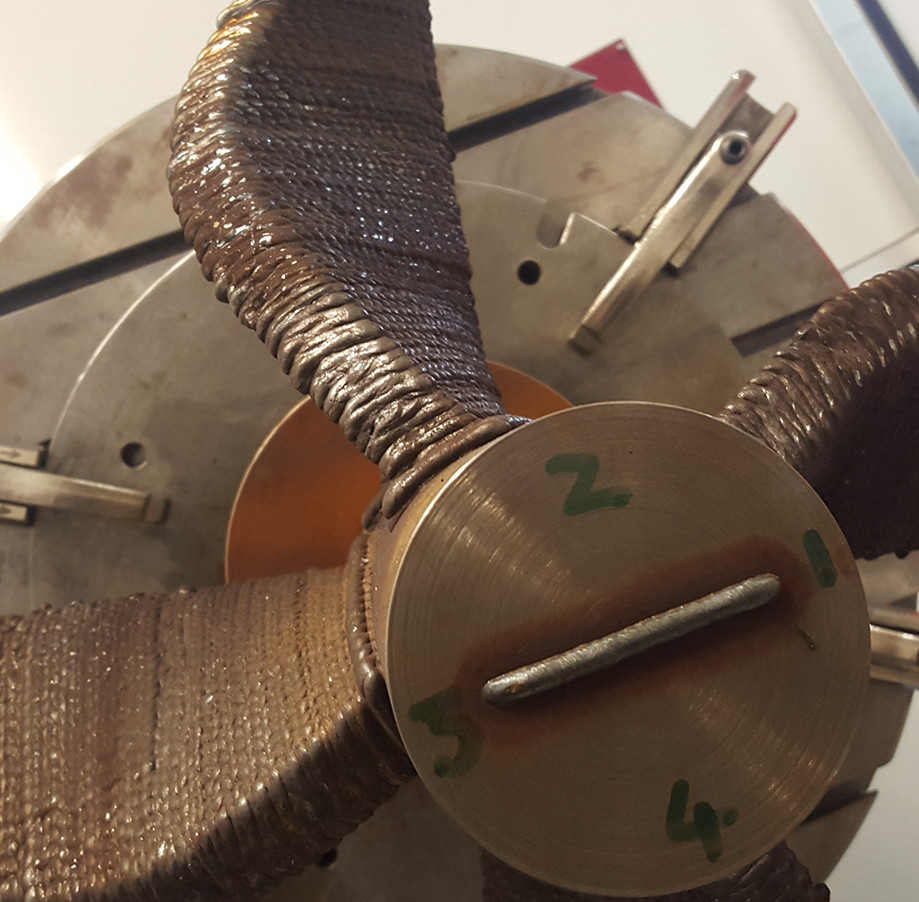

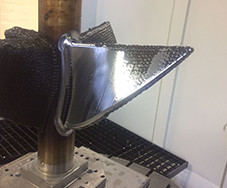

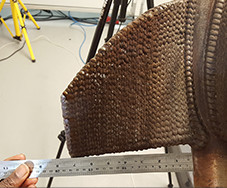

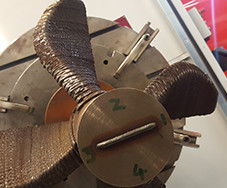

Hybrid Manufacturing Propeller Blade

Sometimes to save time and money or produce complex geometries with very tight tolerances, hybrid manufacturing is the best solution. This boat propeller was first built additively with Powershape, Powermill, and a 6 axis robotic welding arm with 2 external rotary axis. Importing the 3D model into Powermill, we were able to generating additive toolpath algorithms followed by multi-axis toolpath simulation, giving us the ability to prescribe the exact motion of the robot arm in the robot’s own native language. To achieve a smooth surface finish and the requisite tolerances, this piece was then finished using more traditional CNC methods.